Falling film evaporators are relatively simple systems, however, there are many fine details which are important for creating an efficient and effective system. One such detail is the importance of an effective fluid dispersion apparatus. Different fluid distribution techniques can have a magnitude of difference with respect to throughput rates, residual solvents, and reducing thermal degradation.

Why is fluid distribution important?

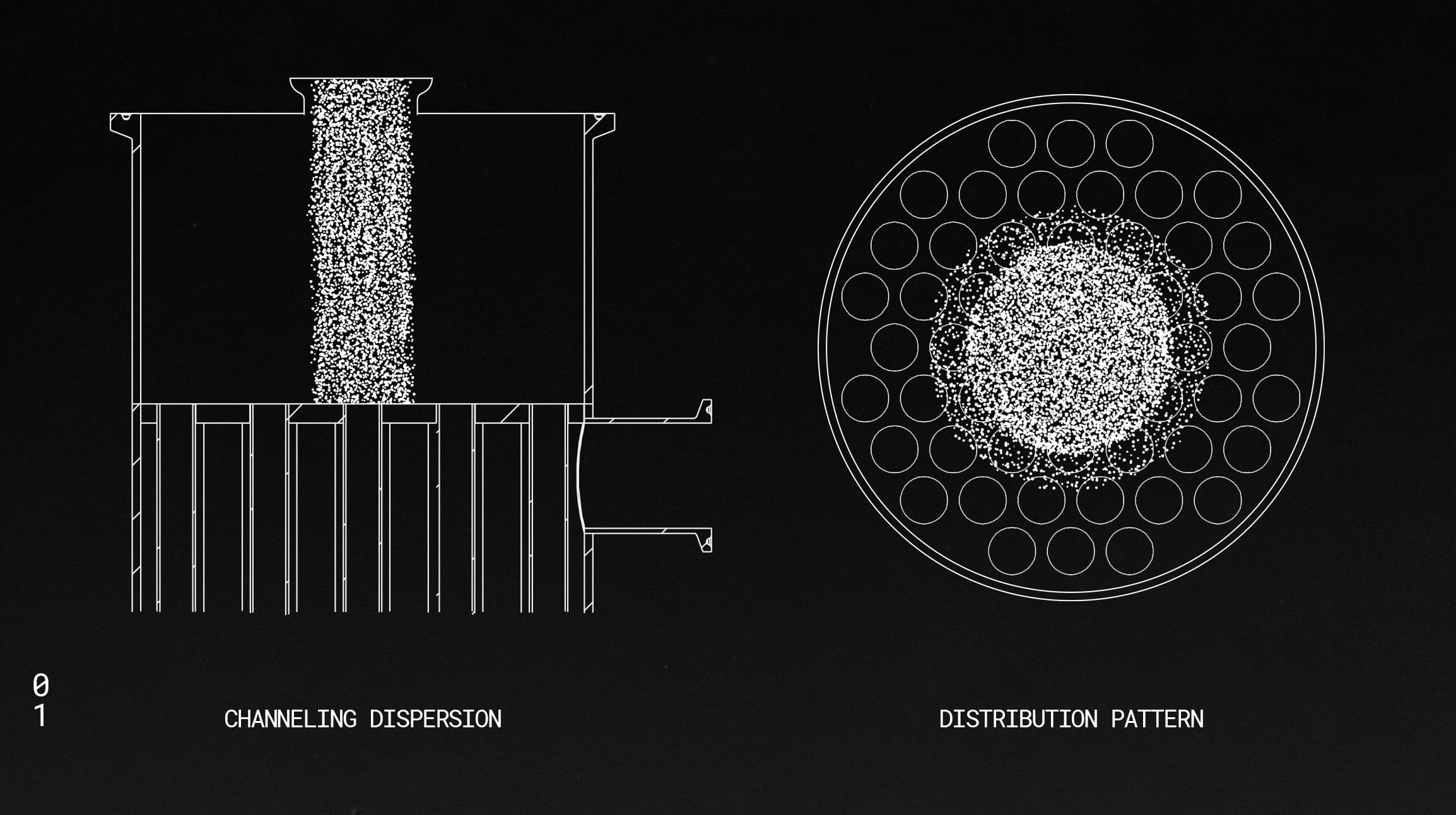

Falling film evaporators function by pumping a solution into the top of the evaporator, where it drips down a bundle of heated tubes. The heated tubes cause the solution to heat up, resulting in solvent evaporating out of the solution. In our evaporators, we use a bundle of 55 tubes making up a surface area of approximately 2m2. However, since the liquid is injected from the top, it is a challenge to make sure that all 55 tubes are used. Without the use of a dispersion apparatus there will be channeling, meaning that liquid will only travel through the inner cluster of heated tubes.

This is problematic for a couple of reasons. First, the throughput rate will be affected because less than 50% of the heating surface is being utilized. This obviously will cause a large decrease in the volume of evaporated solvent that is possible.

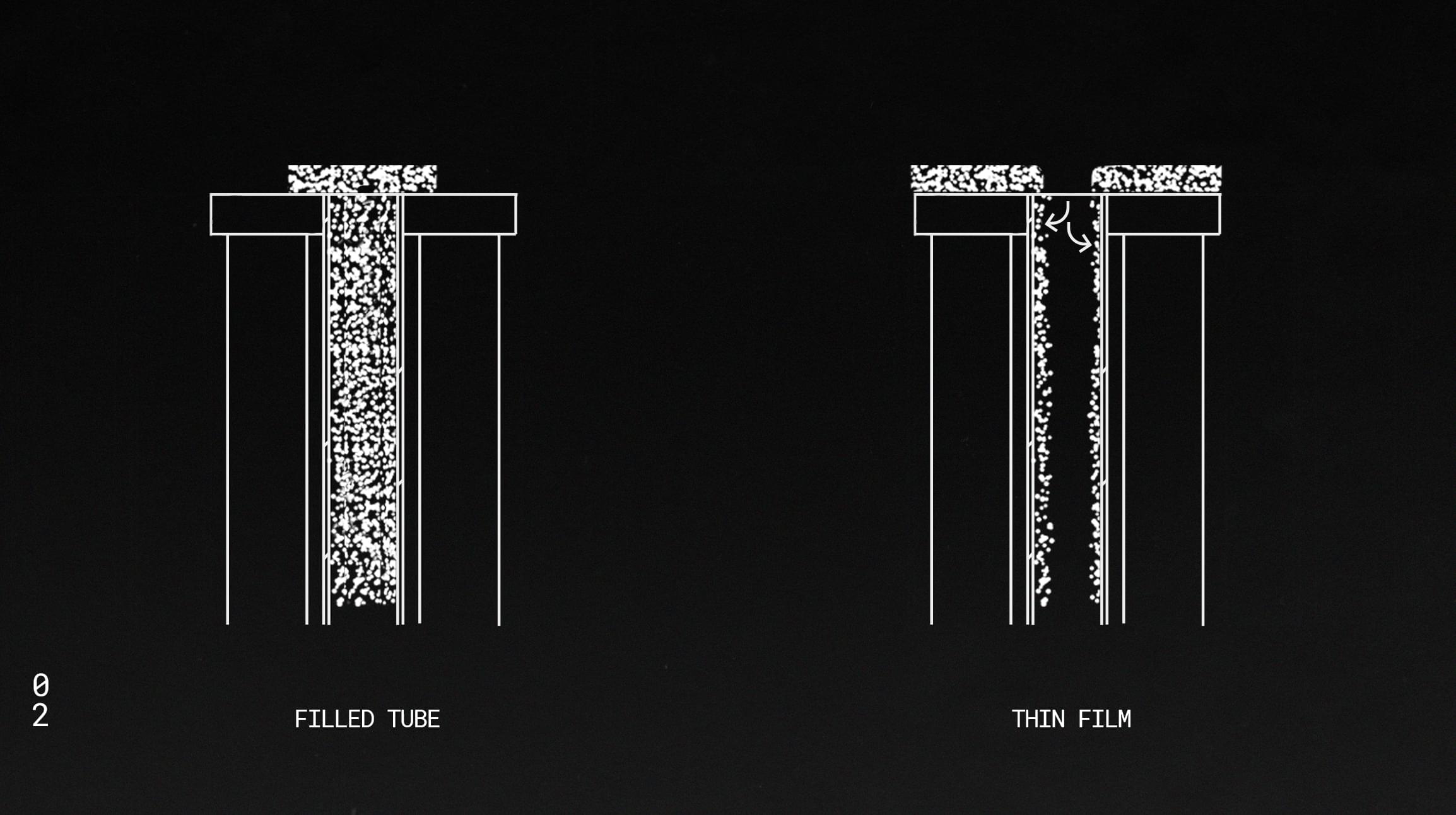

Secondly, forcing all the solution down a smaller amount of tubes will fill the tubes. When effective dispersion has occurred, the evaporation of the solvent has the effect of forcing the incoming solvent to the surfaces of the tubes. When the tubes are filled, the solution does not get forced to the heated surfaces, and is instead quickly pushed out of the tubes. Less solution contacting the heated surfaces will cause higher residual solvent in the end product.

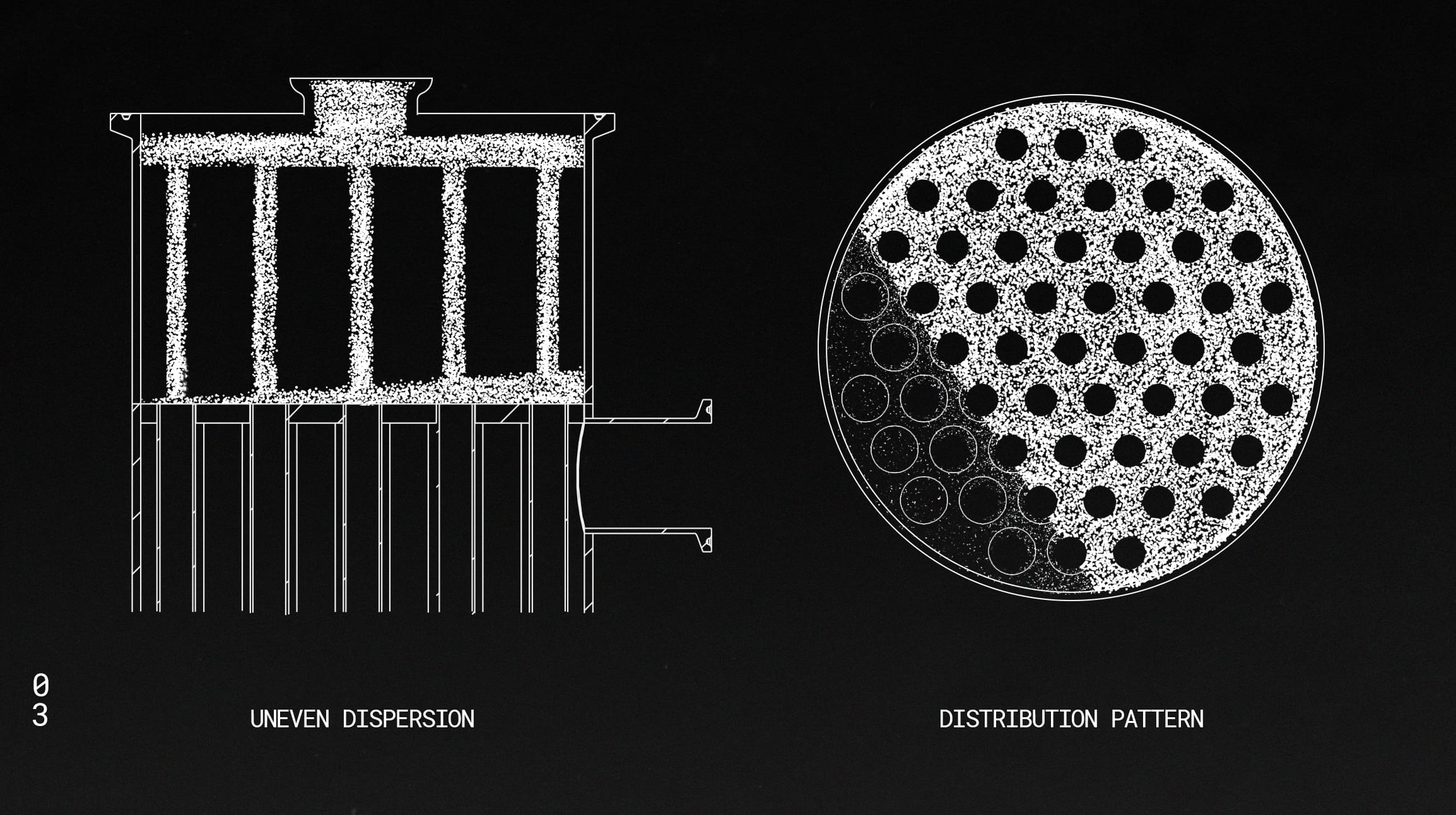

It should be noted that the same things can be said for the importance of a level evaporator. Even with a dispersion apparatus, gravity will cause liquid in an uneven evaporator to flow to one side or another. It likely would not have as dramatic effect, but leveling can play a crucial role in maximizing evaporator efficiency.

By preventing channeling in the evaporator column and supplying liquid evenly to all tubes, the dispersion apparatus can increase evaporation rates by more than 50%.

How do you distribute liquid?

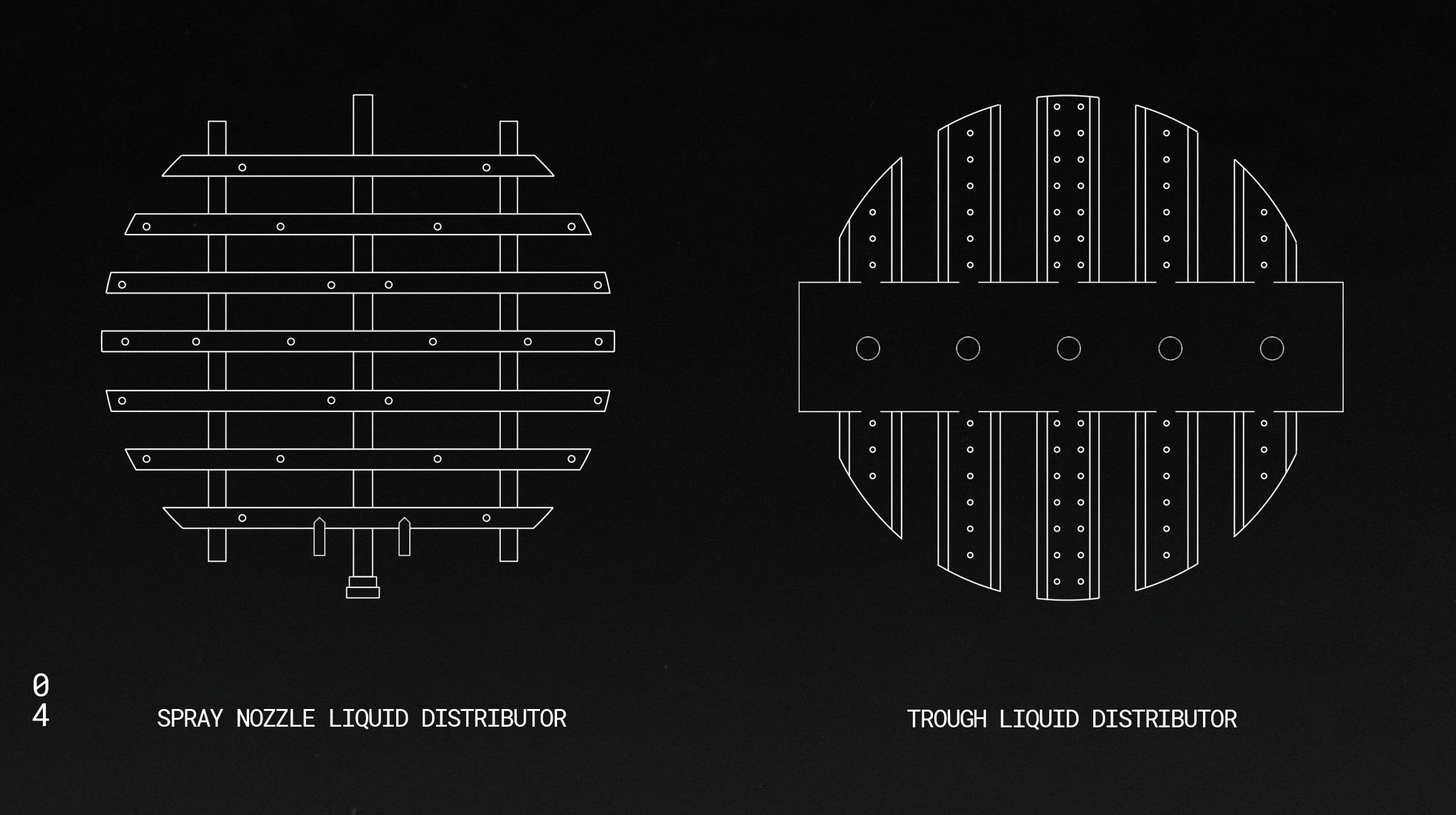

Fluid distribution in a column is an issue that existed long before the cannabis and hemp industries came around. Below are a couple of examples of liquid distributors used in other industries.

As you can see, they use different strategies, but the goal is to spread liquid throughout the column. While some variation of these would likely work for our evaporators, these devices were designed for large-scale evaporator and distillation towers, which are typically over 24” in diameter. It becomes extremely difficult to manufacture something like this to fit in a smaller column, like the 6” ones used on Yellowstone units.

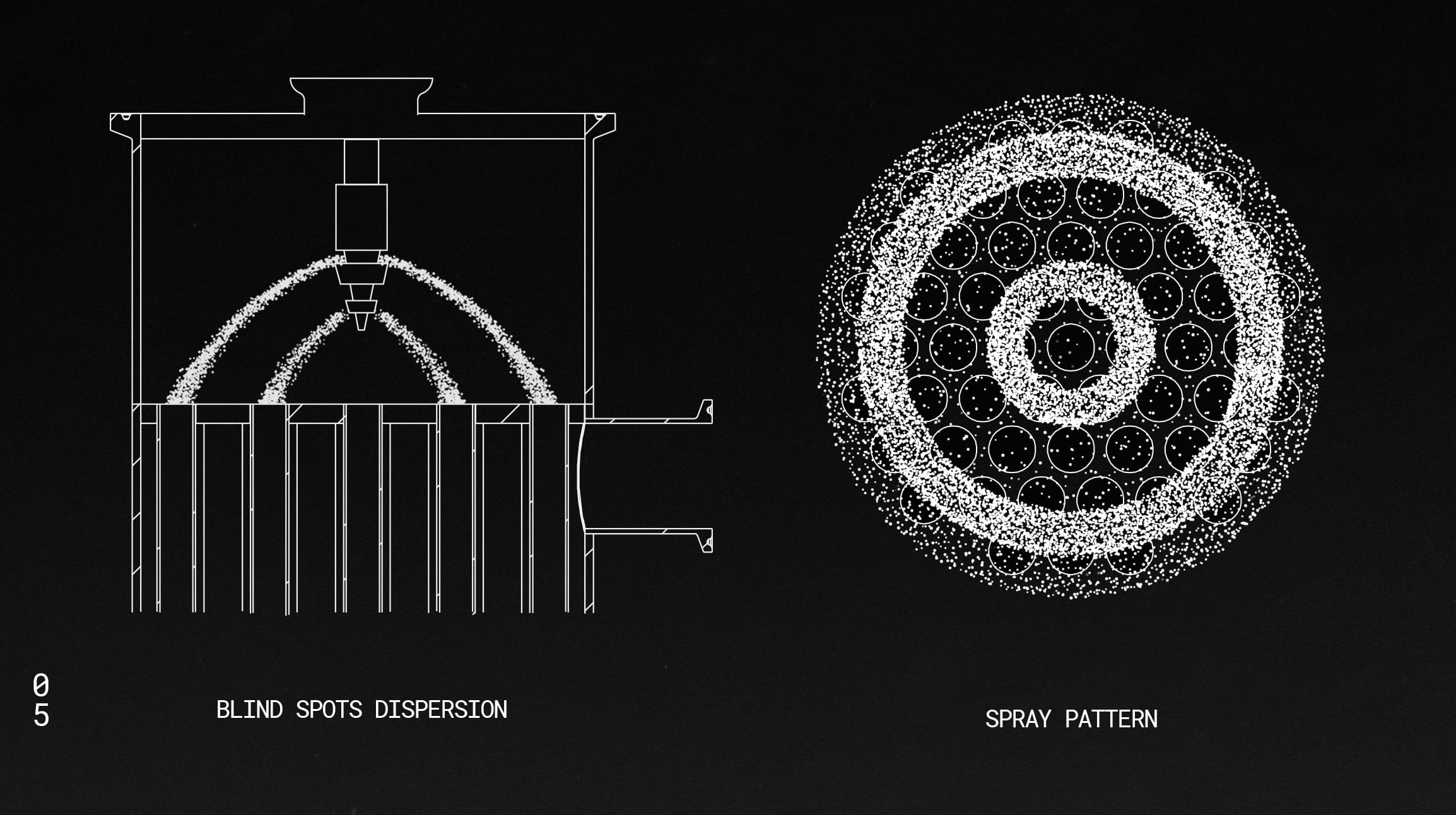

In some evaporators they use nozzles to create dispersion. This can be effective, however there are some drawbacks to this method. First, the solution being sprayed through the nozzle is typically quite sticky. Over time the sticky solution has the potential to block the nozzle, which can affect the spray pattern and prevent certain areas from receiving the liquid. Also, many nozzles inherently have “blind spots” of sorts, where the act of spreading the liquid creates areas where the liquid can not contact.

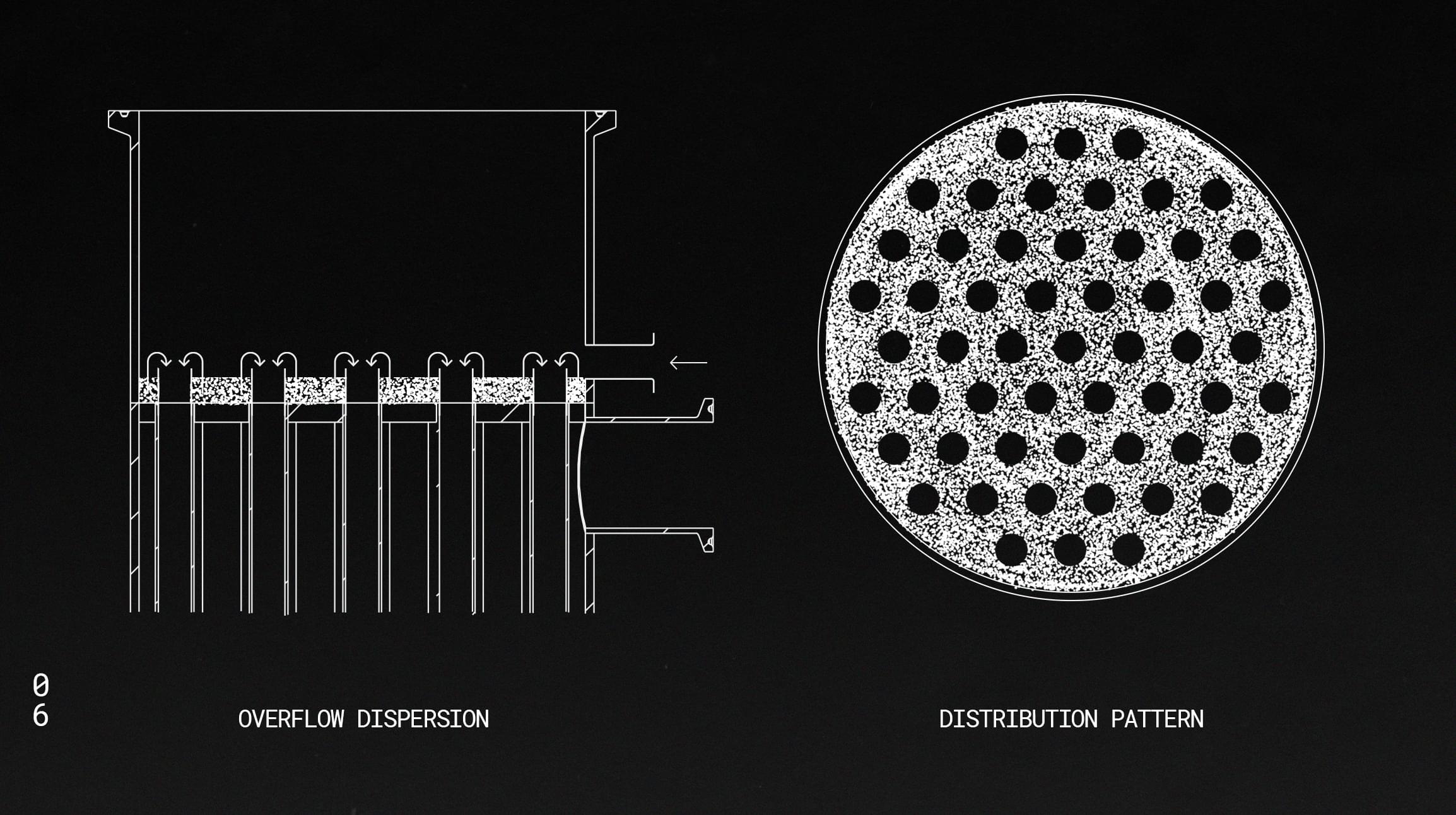

One design which we have seen used in this industry and others is a liquid overflow type of apparatus. In this apparatus, overflow tubes of equal lengths extend past the top of the evaporator. Liquid is typically then pumped in from the side and floods the apparatus. This is a very clever design, as it almost guarantees that liquid will flow evenly into the evaporator, and does a good job of spreading liquid to the tube surfaces. It can be difficult to manufacture, as tubes must be exactly even; a tube which is taller than the others won’t receive any liquid, while a tube which is shorter will hog too much liquid. However, the main drawback of this design is that it is not drainable and difficult to clean. This can result in product losses, and is basically a non-starter when it comes to a GMP implementation.

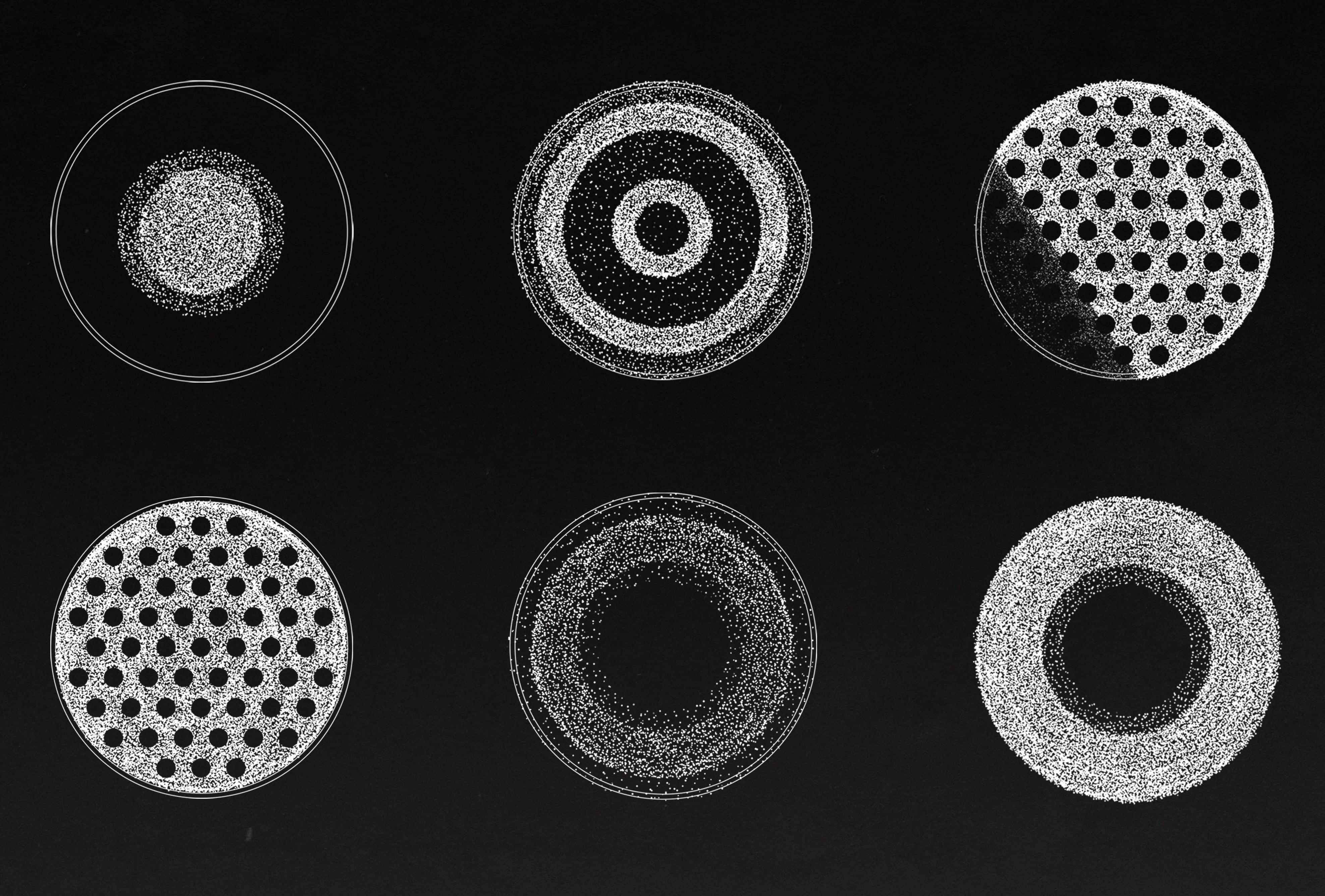

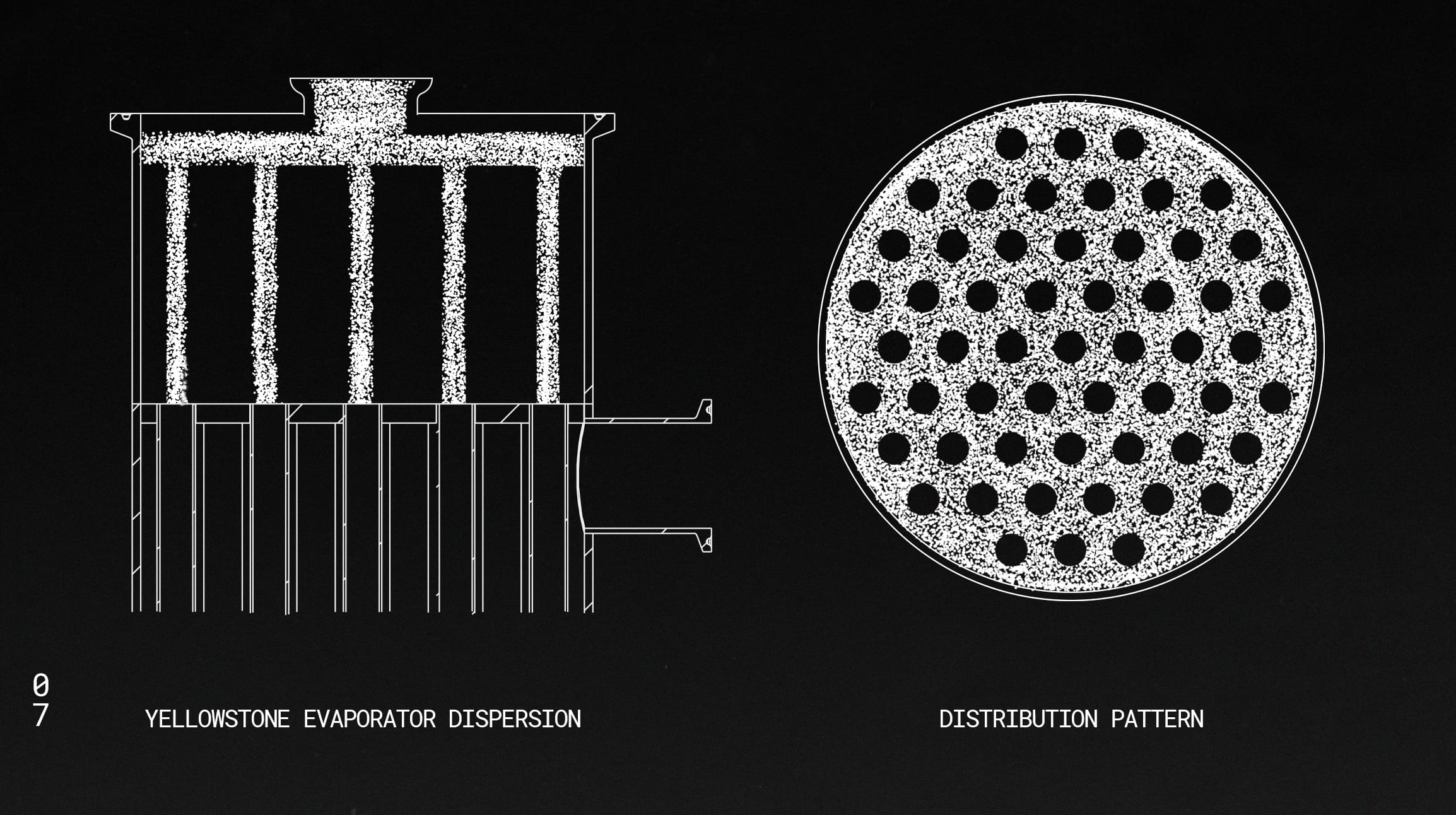

When attempting to solve our own liquid distribution problems for the Yellowstone evaporator, we sought to design something that would be effective, but also simple, easily cleaned, easily manufactured, and removable. We determined that we could take advantage of the surface tension of the liquid and use this to create an even distribution, similar to a shower head. By creating an apparatus with an array of tiny holes, we could ensure that liquid can not drip through holes until there is a slight pressure build above the apparatus, which only happens when the plate is fully covered. The holes in our final design strike a delicate balance; holes that are too small risk clogging and overpressurization, while holes too large do not produce the desired effect.

We feel that our dispersion apparatus is the right mix of effectiveness and simplicity for this application. However, we do recognize that there is more than one effective way to approach when liquid distribution. While it may not be the main factor in a decision, those who are looking to purchase an evaporator should keep things like dispersion in the back of their minds. A dispersion apparatus should certainly be present, and should be suited for the application at hand. A thoughtfully designed dispersion apparatus indicates a dedication to efficiency in a design that likely translates through the entire system.

Yellowstone Extraction Co. has developed an effective solvent dispersion technique for its entire line of falling film evaporators.

Interested in buying? Contact us today.

Request a Quote