FFE Models

Ditch the chiller with the FFE series of falling film evaporators. Offering high solvent recovery rates and unparalleled efficiency, the FFE series saves you money and time. See the information below to learn how you can get a return on your investment sooner.

Request A Quote

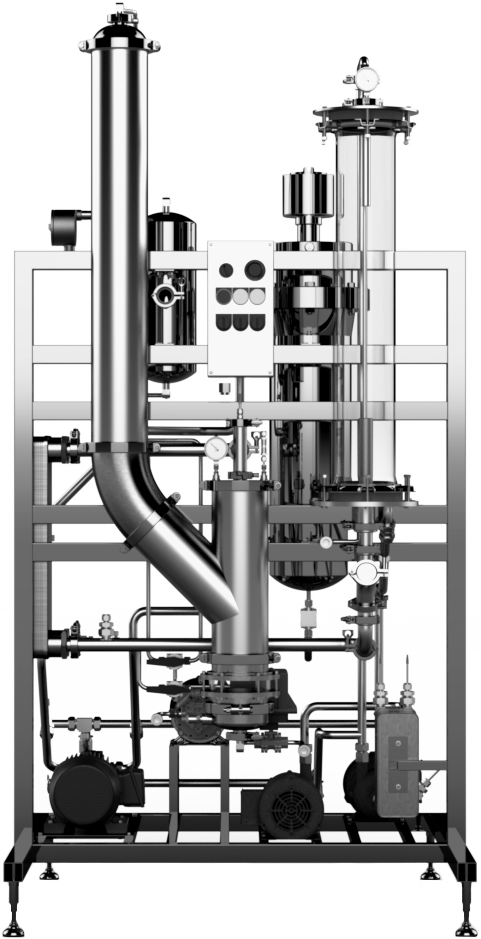

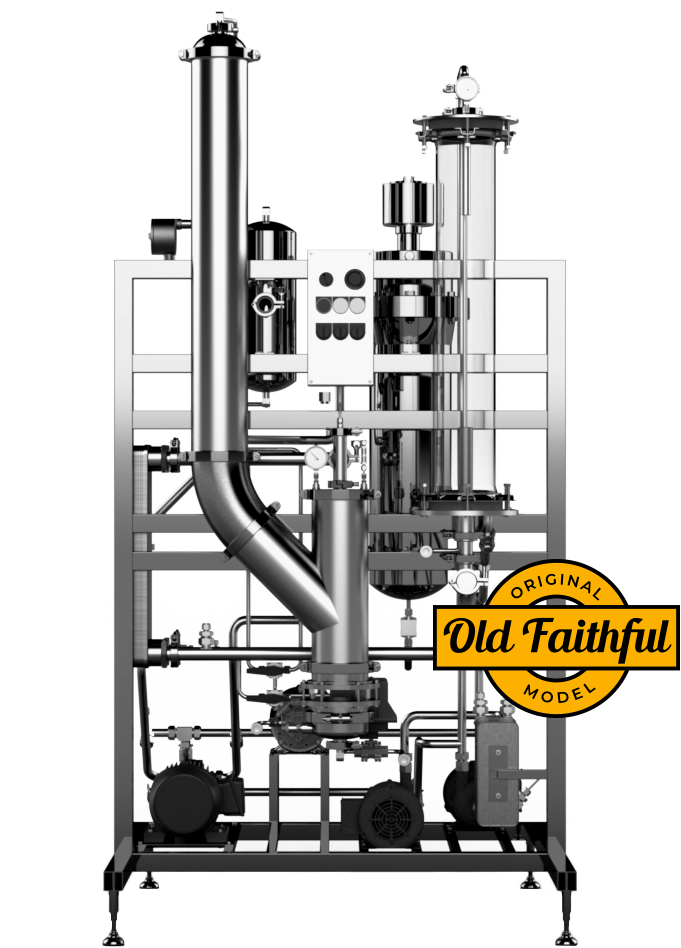

FFE O-Series The Old Faithful Model

The O-Series is our classic design. Revolutionary condensing technology makes the O-Series the most efficient evaporator on the market.

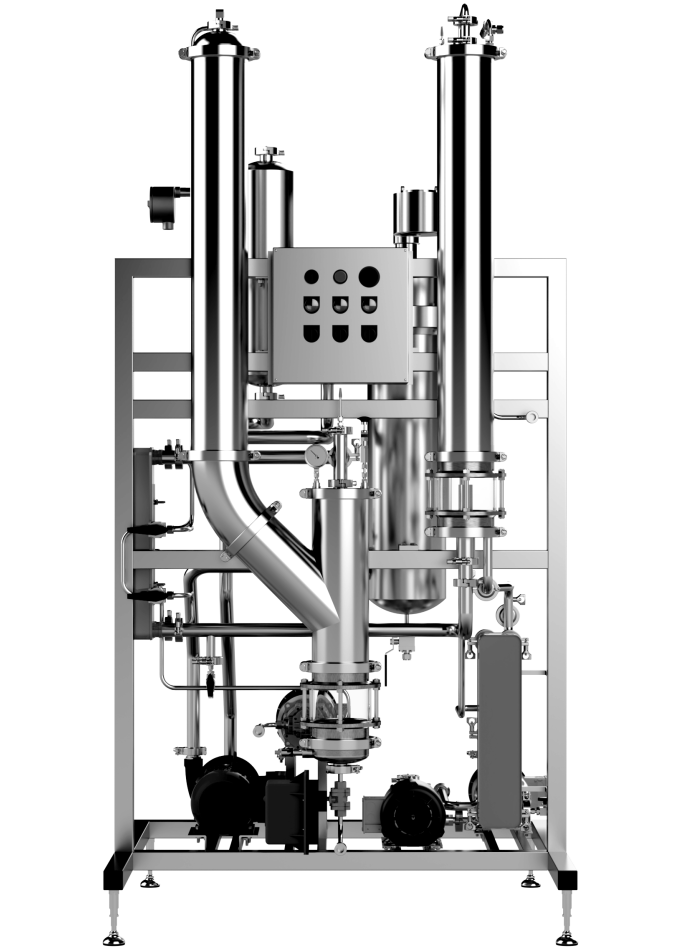

FFE S-Series The Specialized Model

The S-Series provides customers with an even higher performance level of evaporation with more in-depth controls to achieve optimal processing workflow.

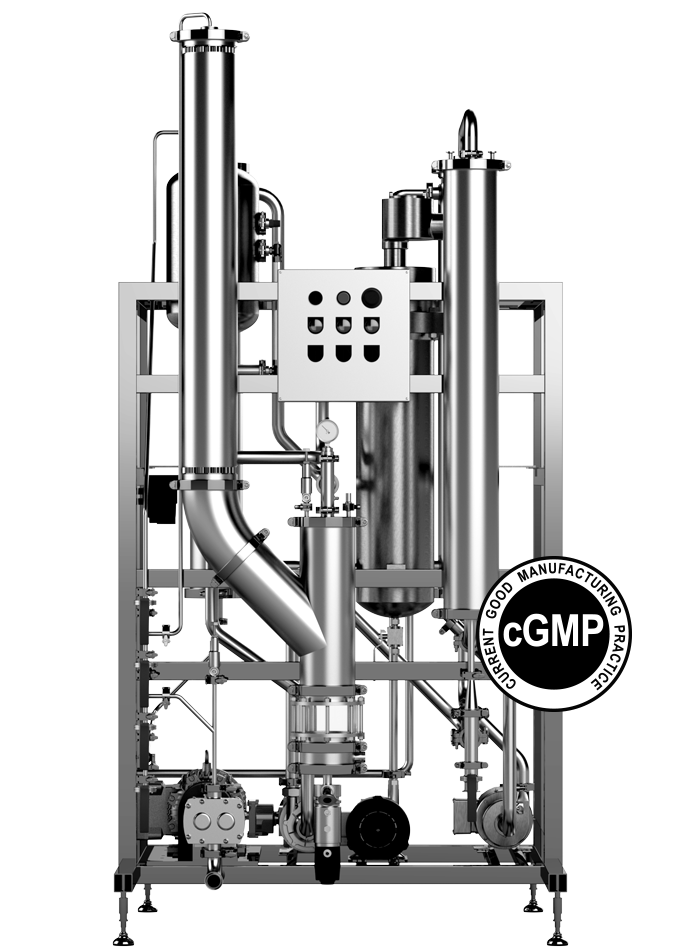

FFE S-Series Pro The GMP Model

Traceability, drainability, and high quality materials make the S-Series Pro the right choice for GMP processing facilities.

Capacity

Classification

Solvent Compatibility

- Ethanol

- Methanol

- Isopropyl Alcohol

Thermal Fluid Pump Rate

GMP Compliant

Additional Features

- Ethanol

- Methanol

- Isopropyl Alcohol

- Hexane

- Heptane

- Ethanol

- Methanol

- Isopropyl Alcohol

- Hexane

- Heptane

Different By Design TM

Different By Design TM

Unit throughput and efficiency are the most important things to consider when building a processing facility. This is where the Yellowstone FFE sets itself apart.

- 250-300 LPH

- 99% Recovery

- Space Saving Design

- Quality Build

- 316 Stainless

- No Chiller Required

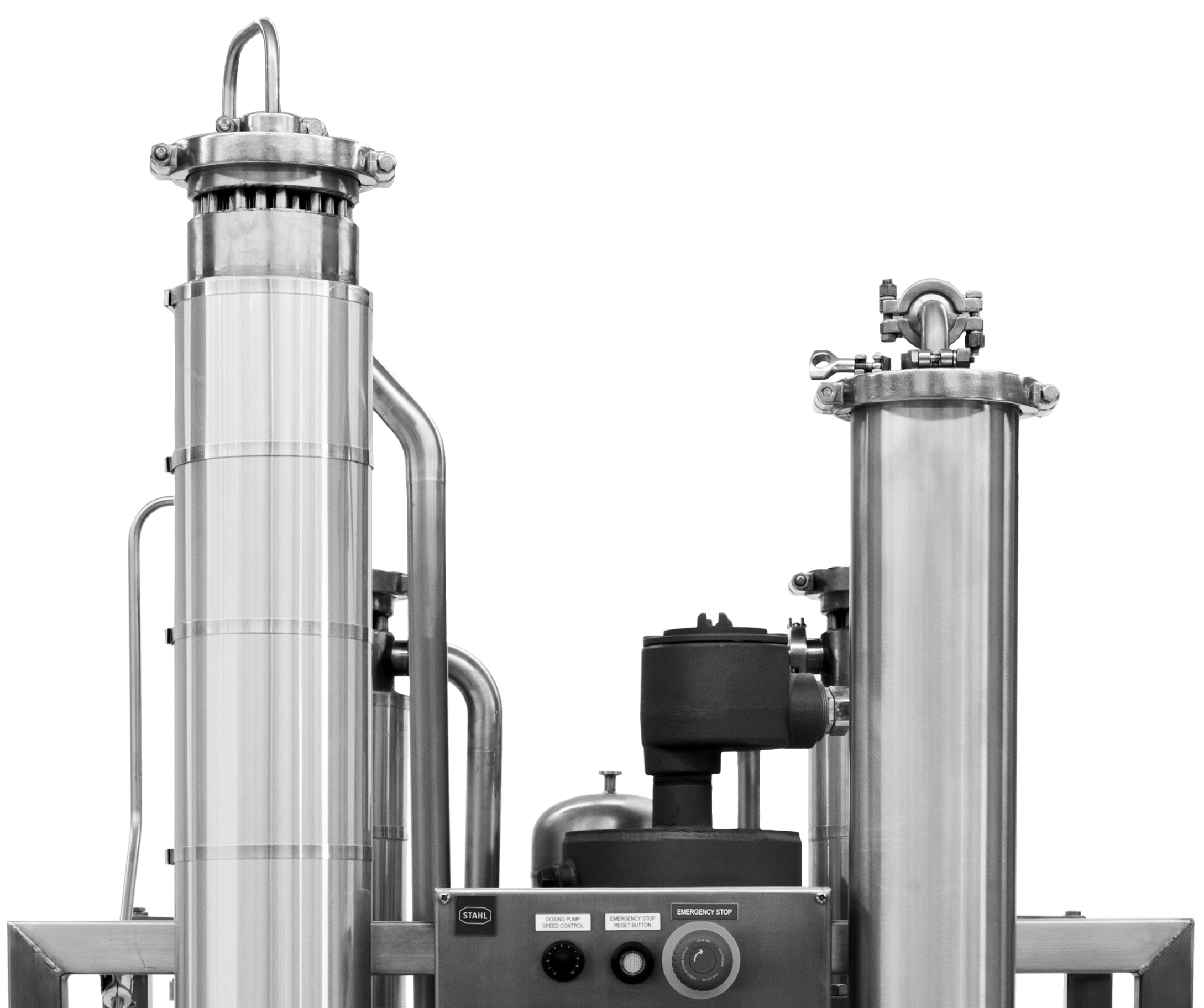

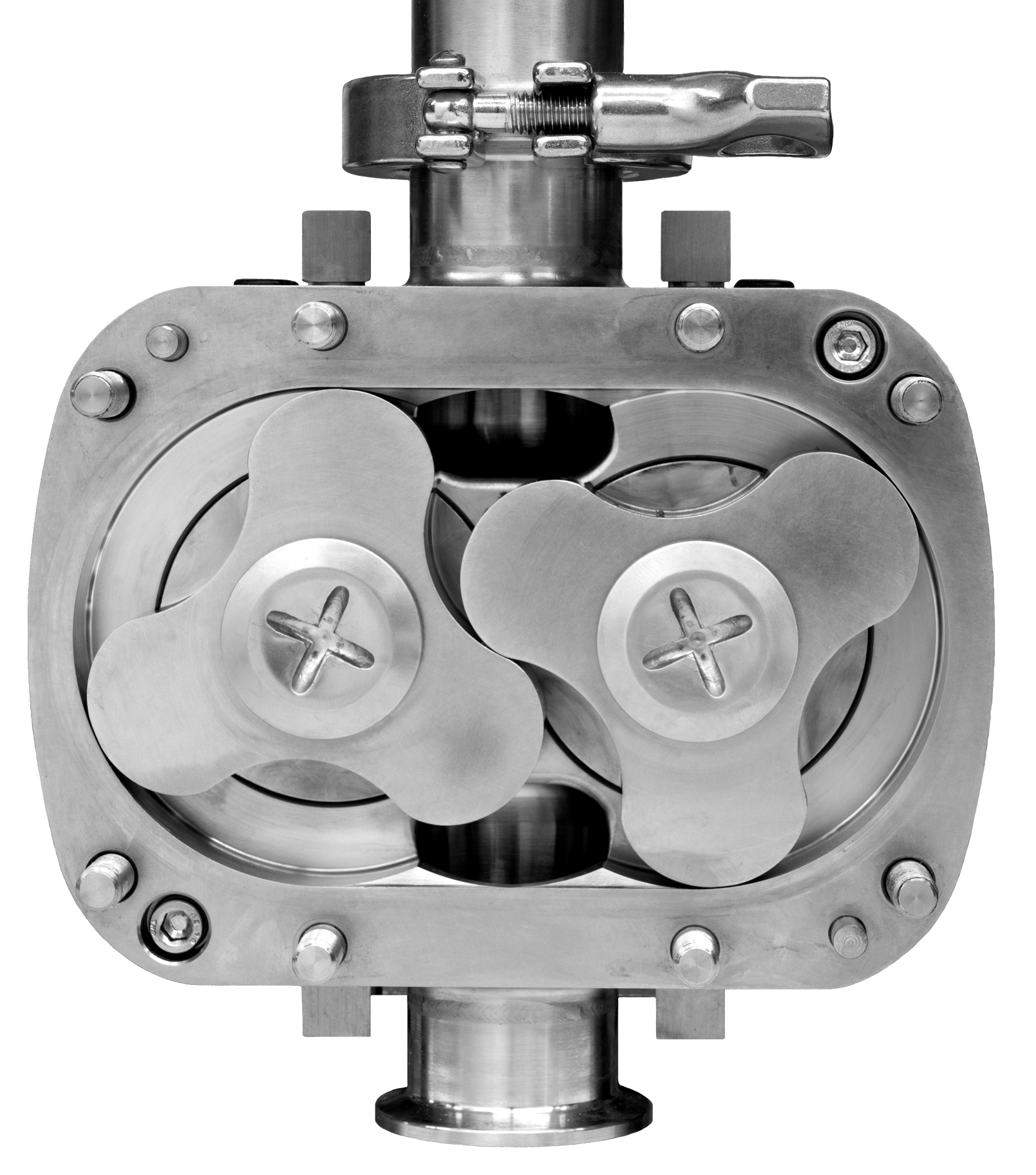

FFE S-Series Pro model.

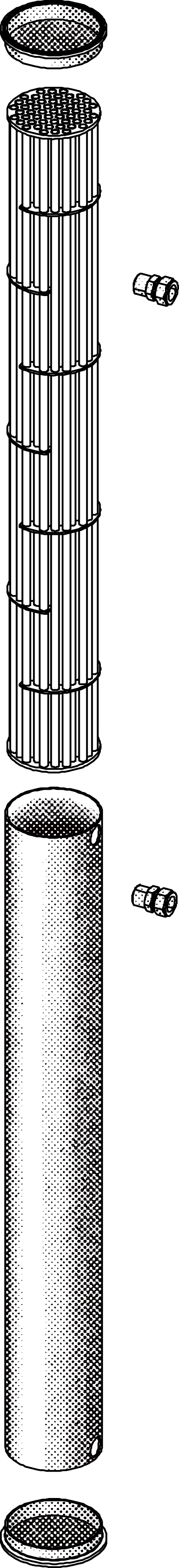

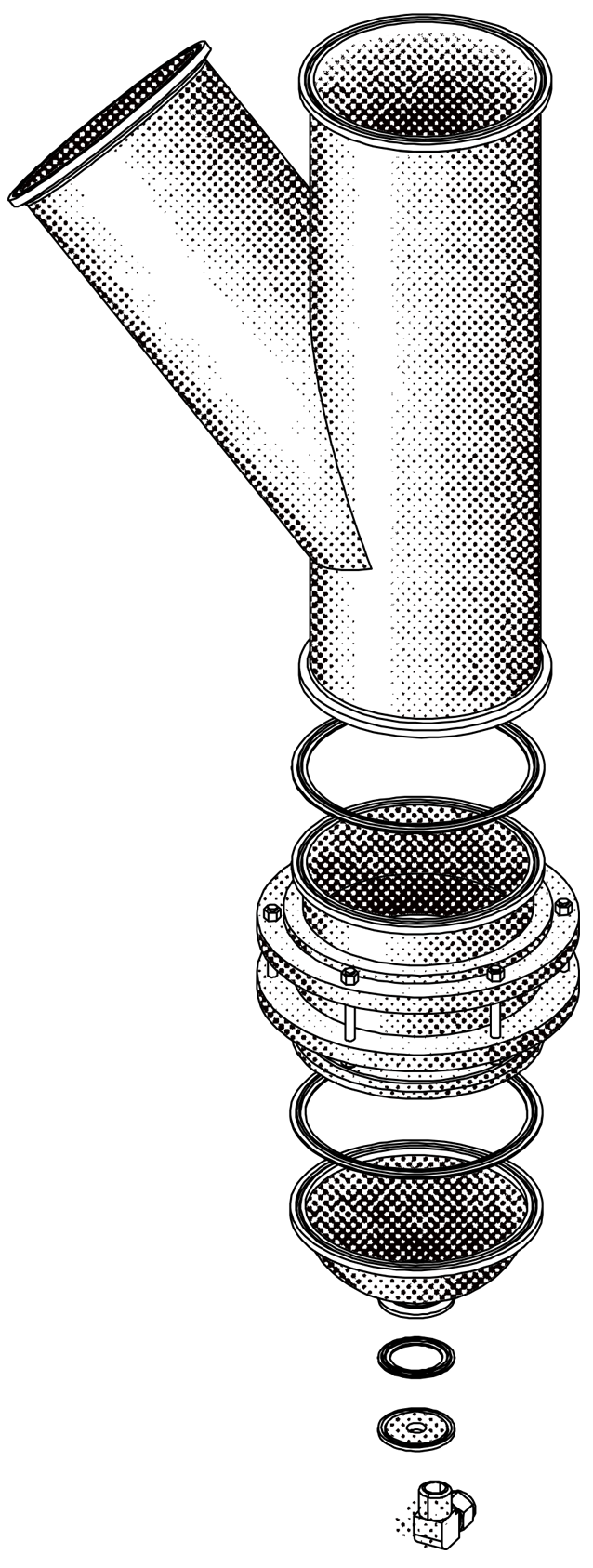

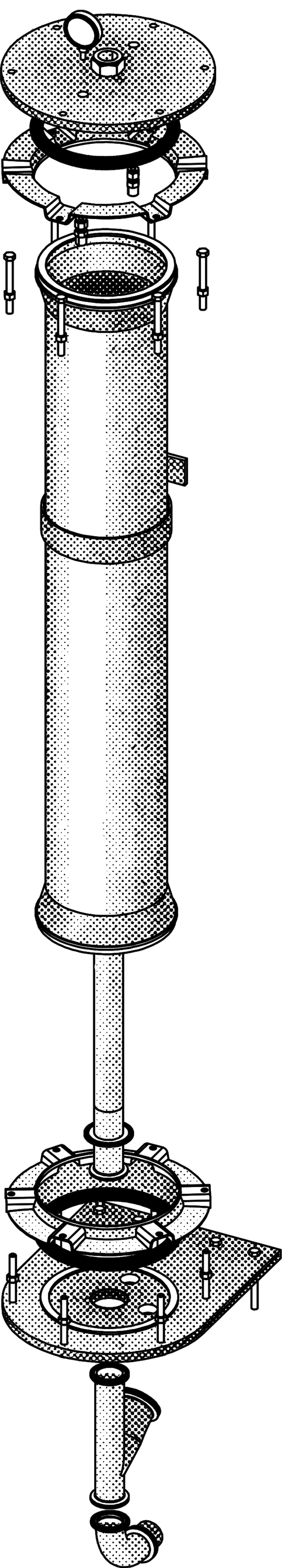

Unique Build & Innovation

Yellowstone FFE units outperform the competition for a reason. Through our proprietary modular approach to design, our teams consistently innovate at every stage of the FFE process (heating, evaporation, cooling) and output industry leading technology at every stage of the evaporation process.

Because others do everything. We do FFE.

Easy To Use

Switch it on & turn it up, it’s that easy.

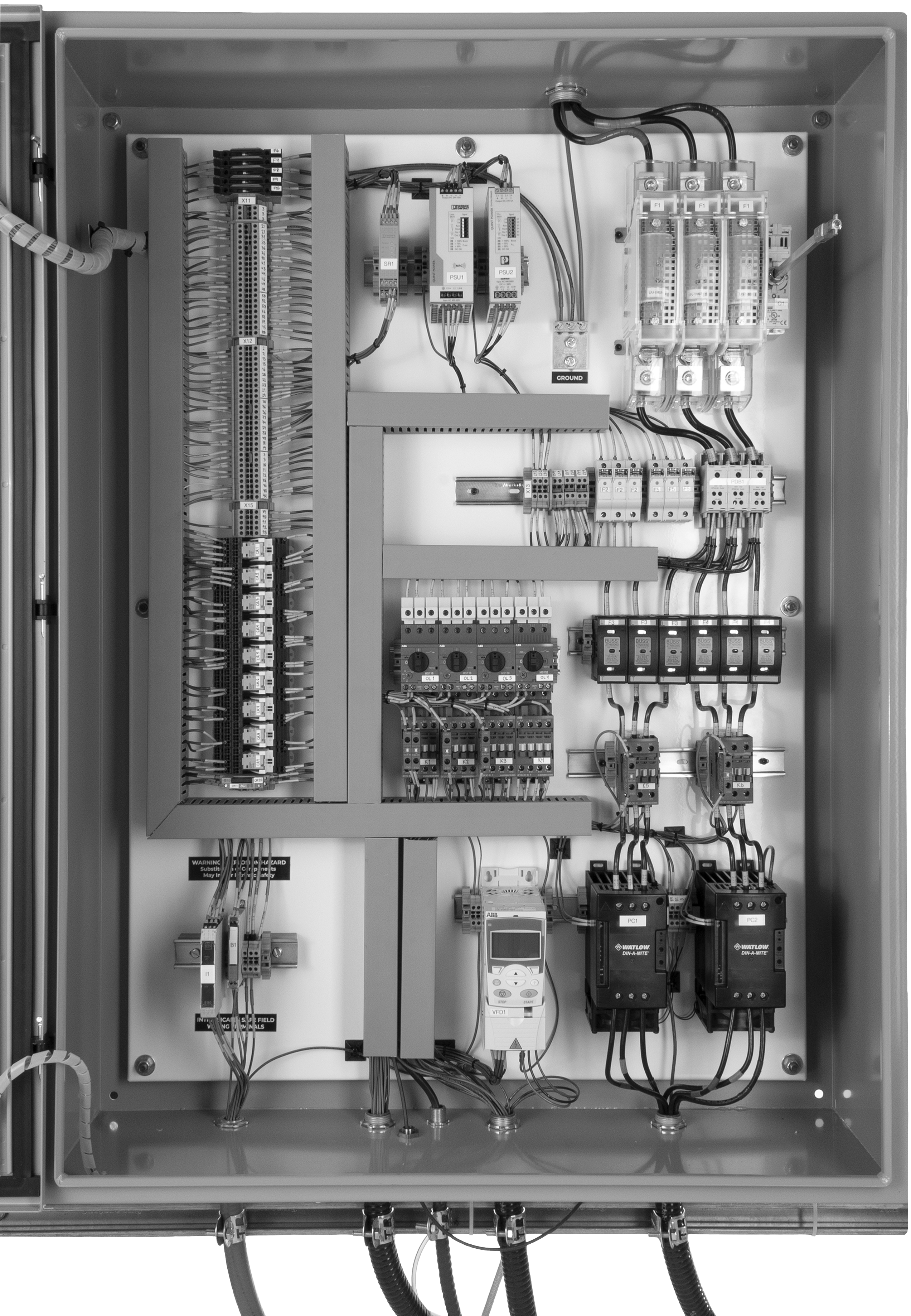

Startup of a Yellowstone FFE requires turning three switches and setting the dosing rate. After that, operators just need to monitor and occasionally tweak system conditions to optimize the product output.

No Pressure

No steam, no added costs, no pressure.

Unlike steam generators, Yellowstone’s onboard heating system isn’t subject to pressure vessel regulations, doesn’t require additional investment, doesn’t expand the machine’s footprint, and does not require complicated installs and servicing. Simplicity in the heating system means less chance for down-time.

Continuous Operation

Our Falling Film Evaporator integrates automatic control systems for ease of use and to decrease processing times. The dosing pump and automated draining systems allow for continuous operation with minimal operator input. Our proven evaporation and condensation rates ensure that you will be left with high purity concentrates and solvents, achieved at rapid speeds.

Chill Without The Chiller

Patent-pending technology works to rapidly condense all the solvent vapor. This is by far the most economical and energy-efficient condenser available in the industry, as it replaces pricey chillers with a radiator requiring less energy input.

Costs

Energy

Technology

Our FFE Condenser

Higher surface area means more effective heat transfer. This is what makes our Diffusion Condenser the most efficient condenser on the market. Vapor bubbles are completely enveloped in cooled solvent, creating the highest possible surface interaction. This drastically reduces the cooling required, completely eliminating the need for chillers.

Paired With

Our Fluid Cooler

In order to maintain the condenser temperature, the condenser reservoir is constantly cooled with a circulated water loop. The system heat is then removed as the water travels through an outdoor radiator assembly. This is a much more efficient and affordable cooling method than chiller-based systems.

5 Year Energy Cost Comparison

Our Condenser's Energy Usage 2.16kw @ $0.12/kWh @ 40 hrs/wk for 52 weeks/year = $539

Comparable Chiller's Energy Usage 45kw @ $0.12/kWh @ 40 hrs/wk for 52 weeks/year = $11,232

* based on average 2020 electricity rates of $0.12/kWh

† assuming chiller energy usage of 45kW

‡ assuming a chiller COP of 1.35

Safety First

When working in hazardous locations, failure is unforgiving and consequences are dire. Because of this, safety is at the forefront of our engineering team’s design decisions. Our designs have multiple redundant fail safe mechanisms to ensure that hazards to the operator are statistically eliminated. We perform sensitive FMEA (Failure Modes and Effects Analysis) and design our machines such in the event of a component failure, we can rely on alternate safety devices.

Triple Redundancy

Failsafe

How Our FFE Works

Machine Specifications

Machine Specifications

- Voltage

- 480 V 3 Phase

- Amperage

- 75.5A - 82A

- Wattage

- 60 kW

- Alcohol Recovery Rate

- 250-300 LPH

(66-79 GPH) - Operational Footprint

- 4' x 4' x 8'

- Solute Max Temperature

- 194 °F (90 °C)

- Dwell Time

- 5 Seconds

- Additional Equipment Included

- Radiator & Control Panel

High Quality Manufacturing

Yellowstone equipment is designed, assembled, and tested in Canada. Quality is at the forefront of our manufacturing process, which is why our facility's quality management system is certified to the internationally recognized ISO 9001:2015 standard.

Contact us

for product pricing